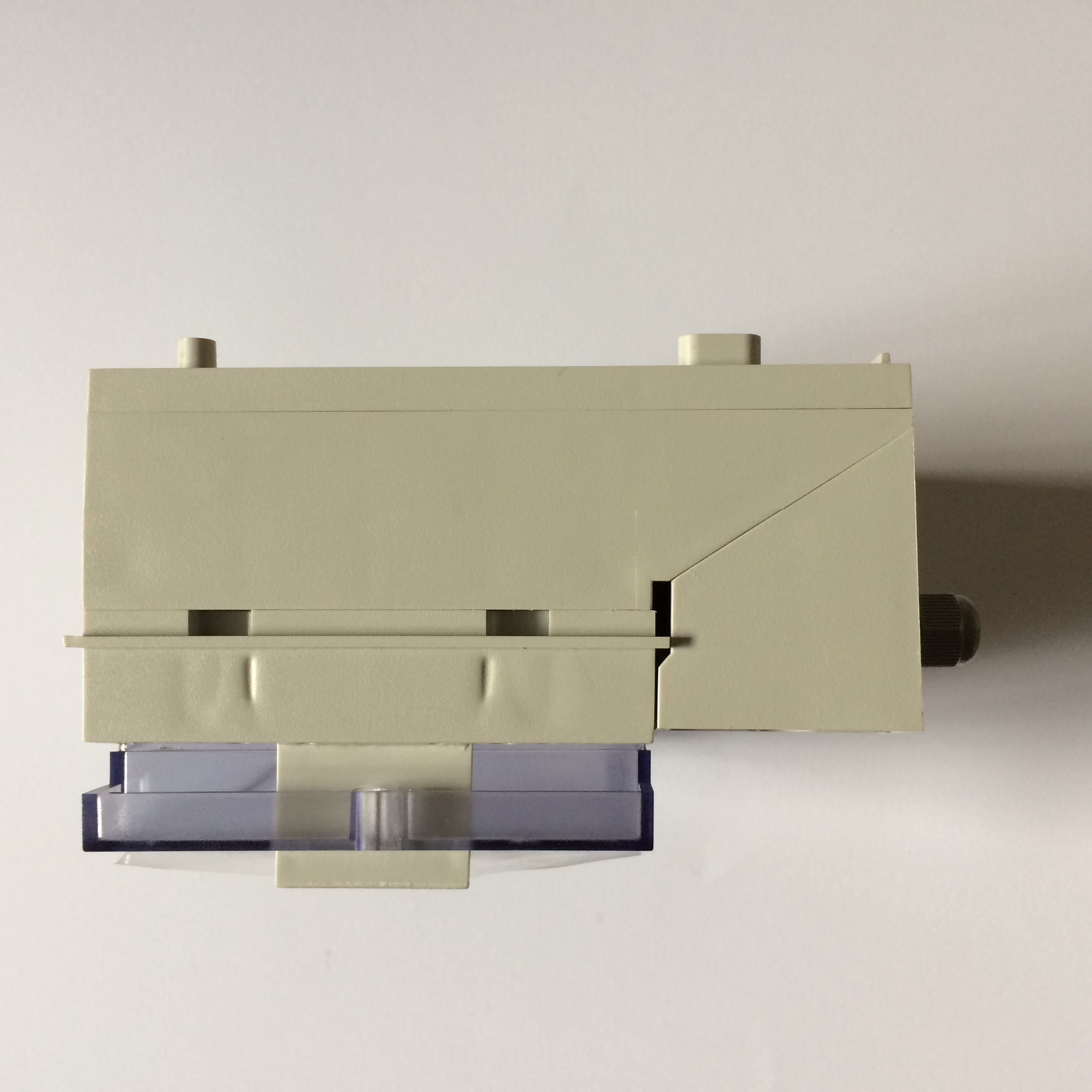

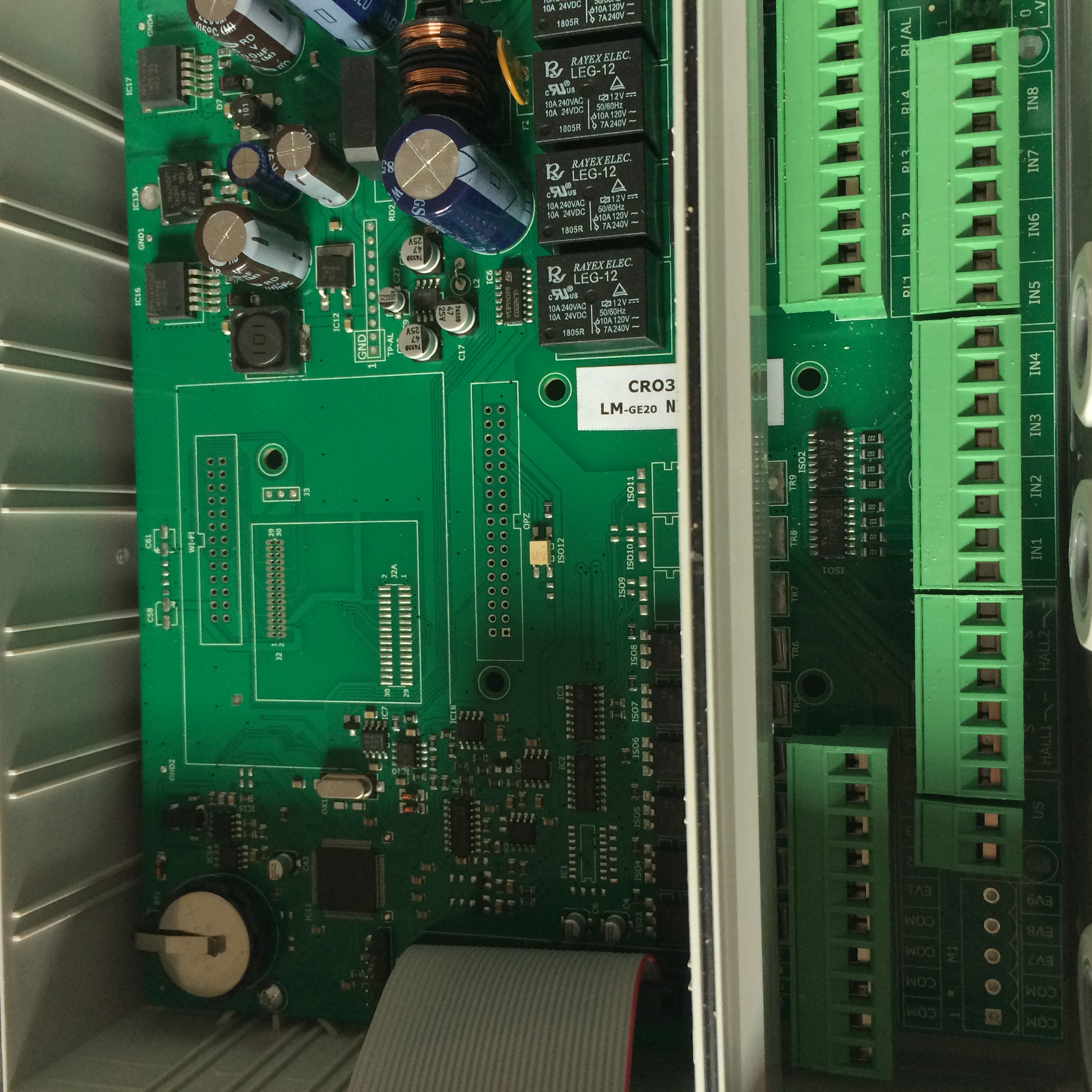

- wide visibility display – 64 x 128 pixels

- USB port to download hystorical data and upload new SW version

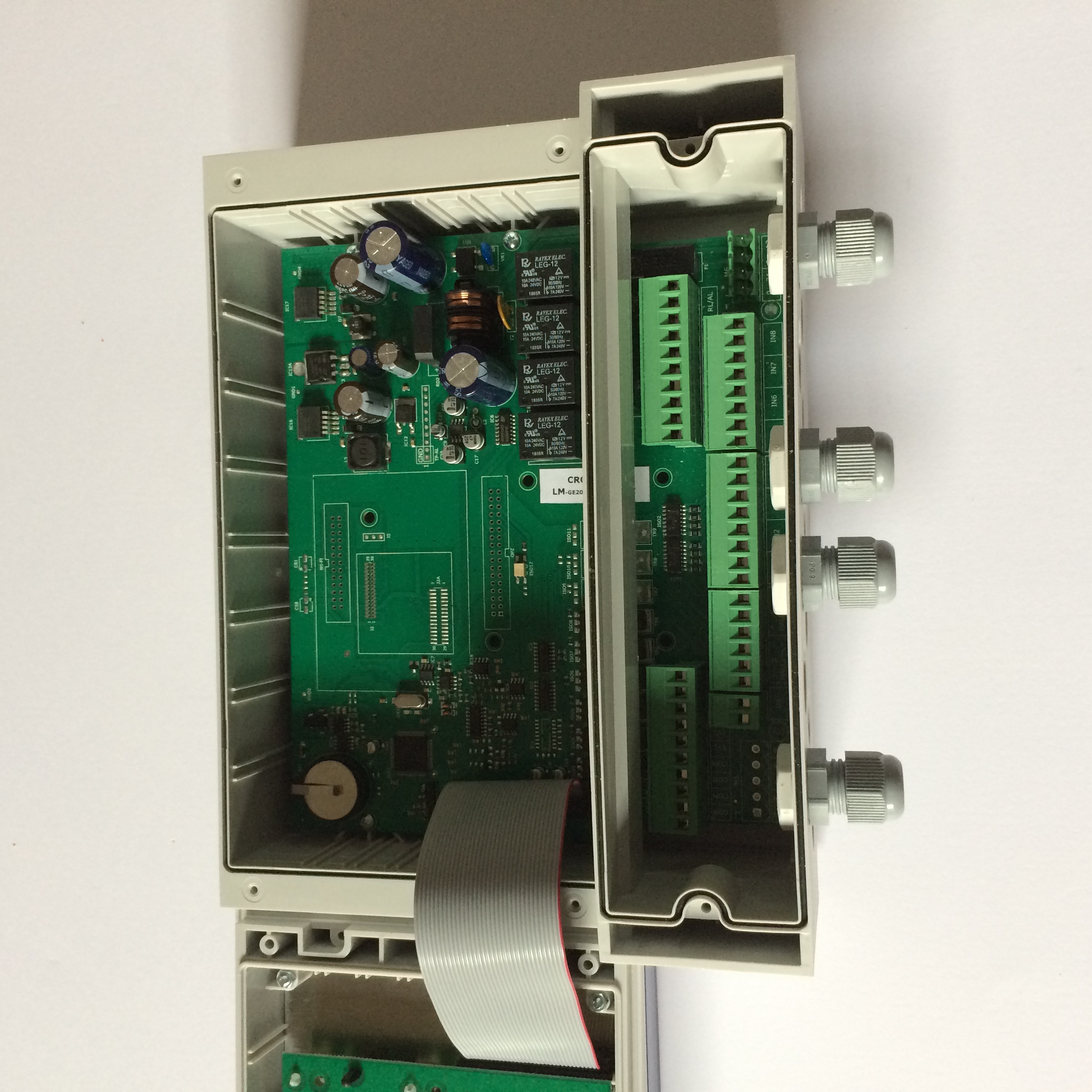

- 6 outlets – 24 Vac – to pilot several R.O. operating modes

- inlets for minimum and maximum pressure sensors

- inlet for pump thermal

- inlets for minimum and maximum level sensors

- 3 additional inlets to read external signals

- 3 relays to pilot dosing pumps with 3 different operating modes

- relay to activate an external alarm

- relay to signal the production in progress

- 2 inlets for water meters (hall/reed type) seatable in different ways

- conductivity inlet with wide possibility of calibration and compensation

- fully-developed operating SW to pilot high quality industrial R.O.

- wide possibility to set the R.O. functioning, to face every needs

- stand-by and flushing functions already set up and selectable

- over 15 different kind of alarms to a safe and perfect plant running

- automatic memorizing of the last 2.000 events/alarms

- possibility on request, to make SW changes to satisfy every specif customer needs

HOW IT WORKS

The controller OSMOSIS KW CONTROL 1 allows to manage industrial reverse osmosis of any size, thanks to an advanced preinstalled software. The controller has multiple inlets/outlets which allows to pilot the osmosis components (pump, solenoid valves, dosing pumps, etc.) and to read signals coming from the external sensors (conductivity, pressure switches, flow meters, etc.).

In order to guarantee an high electrical safety, all the outlets are on low voltage – 24 Vac. Thus the controller has to be connected to an electrical cabinet equipped with secondary relays, which pilot in turn the osmosis components.

A simple guided programming allows to set the different osmosis pharameters to fit them with the specific needs. The fundamental function of stand-by and flushing are already available. The “stand-by” starts the osmosis if there is a too long pause between two productions in order to avoid to stress the osmotic modules. The “flushing” allows to rinse the module at the end of every production to let down the salinity inside.

It is possible to set a minimum working time for the pump to avoid frequent restarts which could damage the reverse osmosis modules.

The production can be controlled through the level sensor of the permeate tank using a single maximum level sensor or through a double sensor (mimimum and maximum) to obtain a more continuos operating phase,with less starts and stops.

There are several alarms already set to monitor the osmosis work (pressure, conductivity, flow rate, etc.). Every alarms can be personalized and it is possible to choose the osmosis status consequently to every alarm happened.

With the standard operating cycle it is possible to drain the permeate produced at the beginning of the cicle, if it has not an adequate quality, thank to the conductivity sensor. The double meter inlet allows to check the permeate and concentrate flow rate and ratio.

A specific programm menu allows to manage the flushing of the modules using osmotized water coming from a specific tank where it has to be collected before. It i salso possible to set the functioning, using a high pressure pump with double stage.

Thanks to 3 relays it is possible to pilot 3 doing pumps normally placed in the osmosis plant to dose anti-scaling products and reducing before the modules and to add protective product in the permeate.The dosing pumps can operate with different modalities (time, frequency, counter) and moreover can be set according to the flow meters reading.

Three specific and dedicated inlets allows to read start/stop signals coming from external devices as filters or softeners in order to synchronize the osmosis operating with others devices existing in the whole plants.

On the front side of the controller there is a USB port with which it is possible to download the hystorical data about the last 2,000 events/alarms to examine them deeply. Moreover it is possible with the USB, to upload a new SW version in the fast and simply way.

A special “safety pen drive” is available in order to enable the “service menu” only if the pen is inserted in the USB port. In this way only authorized people can modify the setting pharameters and it avoids unauthorized changes.